Advantages of thin-gauge electrical steel strips

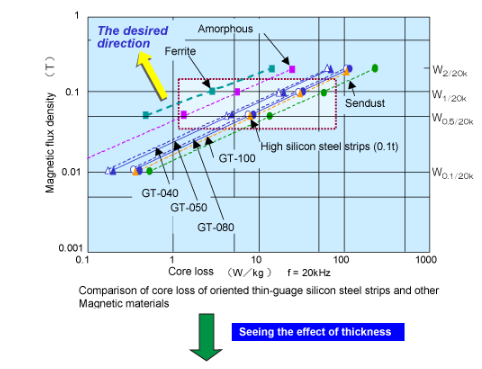

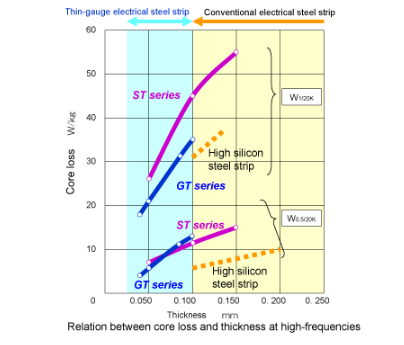

Very

small core loss at high frequencies

Very

small core loss at high frequencies

The thickness significantly effects core loss, therefore, allowing thin with very low core loss at high frequencies to contribute to higher efficiency and saving energy.

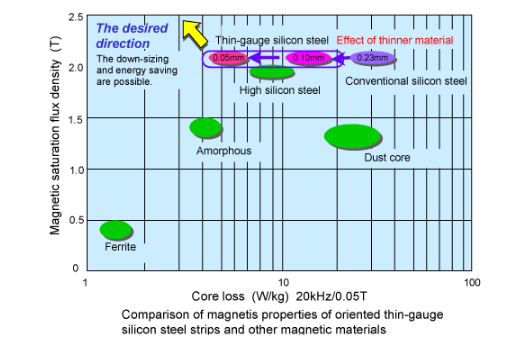

High

saturated flux density

High

saturated flux density

Thin-gauge electrical steel srips contribute to downsizing of high frequency reactors and transformers due to high saturation flux density.

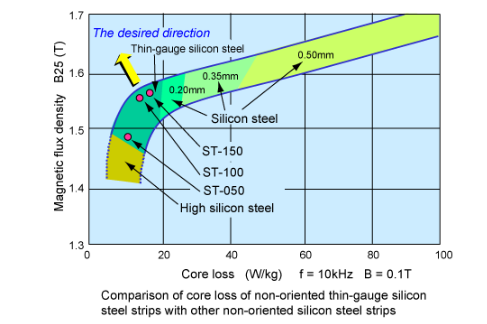

Non-oriented

thin-gauge electrical steel strips have the same properties

Non-oriented

thin-gauge electrical steel strips have the same properties

Non-oriented thin-gauge electrical steel strip is the ideal material due to its low core loss and high saturation flux density.

Thin-gauge

electrical steel strips have excellent insulation coating

Thin-gauge

electrical steel strips have excellent insulation coating

Thin-gauge electrical steel strips have inorganic insulation

coating. This coating allows excellent insulation, which enables the

best stress relief annealing.

To the page top

To the page top